Request a Quote

"*" indicates required fields

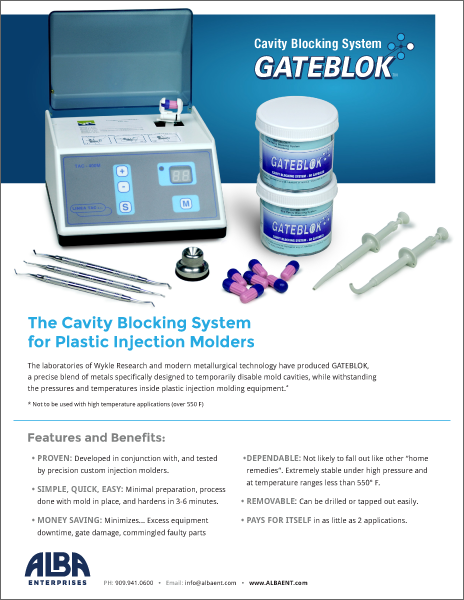

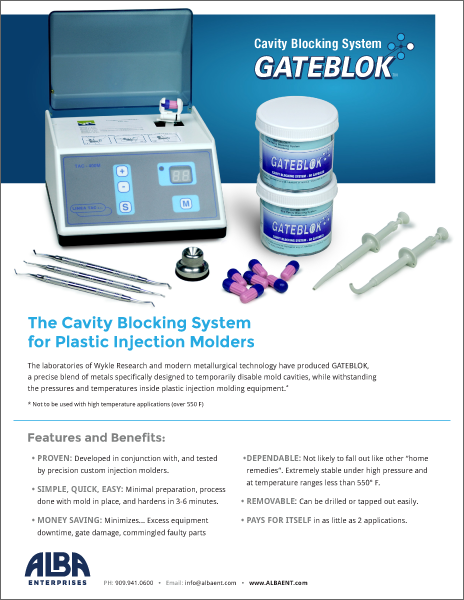

The laboratories of Wykle Research and modern metallurgical technology have produced GATEBLOK, a precise blend of metals specifically designed to to temporarily disable mold cavities, while withstanding the pressures and temperatures inside plastic injection molding equiptment.

Durable, quick and easy to use, GATEBLOK effectively seals off cavities in injection molds. Normally requires a down time of only 5 to 10 minutes, without having to remove the molds.

"*" indicates required fields

Proven

Simple, Quick, Easy

Money Saving

Minimizes…

Dependable

Removable

Pays for Itself

The GateBlok system Includes: