Babyplast 6/12P (horizontal)

By Babyplast

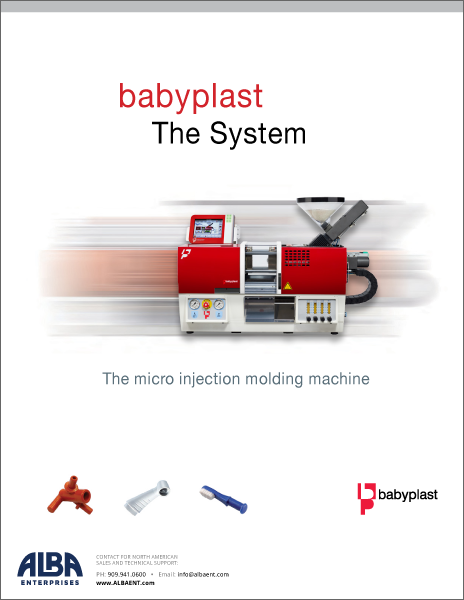

Babyplast the System

Micro-Injection Molding Machine 6/12P

“The ideal machine for the production of micro parts. Suitable for all types of thermoplastic materials up to 420°C, metals (MIM), ceramic (CIM), wax.” – PEEK & CO

Maxi-Performance For Micro-Pieces

The smallest fully hydraulic injection molding machine is the result of experience matured in thousands of applications in the medical, electronic and micro-mechanical sectors and years of research and experimentation in the field of MICRO-INJECTION of thermoplastic materials, MIM (Metal Injection Molding), CIM (Ceramic Injection Molding), LSR (Silicone), Rubber (NBR), Macromelt Holtmelts and waxes.

The Smallest But Greatest

Babyplast 6/12P is one of the smallest, fully hydraulic, injection molding machines. Thanks to the unique concept of the machine platens which act as mold bolsters, the cost and dimensions of the molds are reduced considerably. Babyplast 6/12P occupies less than 0.6m2 of floor space and is extremely quiet (< 68dB)

Precision

Babyplast 6/12P Guarantees the highest precision thanks to the injection piston and pre-plastification of the material. To obtain the optimum volume of material, there are 5 interchangeable pistons available. It is also possible to move the injection unit off center.